Linear Plexiglass door

In this model of the wooden door, only the thickness edge of the glass on the door frame is visible, and its purpose is to show the brightness on the other side of the door frame. In this design, the wooden door is cut with CNC machines and the glass is placed inside the door. In this model, fixed or customer-proposed designs can be used to make the door and frame. Privacy and the desire for a specific level of privacy, along with the brightness of the room (the light being on!), are fully observed in this model. The special beauty and modern or minimalist design of these designs are noteworthy.

Category: Polywood door

Showing the light on the other side of the ledge

This plan has also taken a look at the vista point (being exposed or visible) of the workplace due to the preservation of privacy (privacy and security) of the user's place. It means that only the light on the other side of the door can be recognized, and other things cannot be seen and recognized.

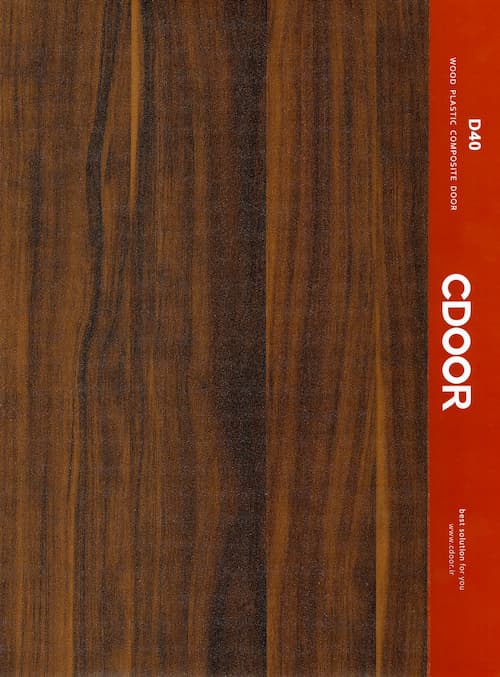

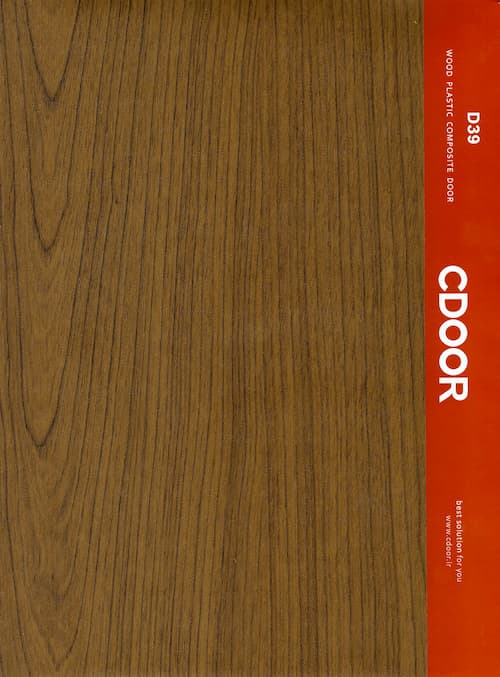

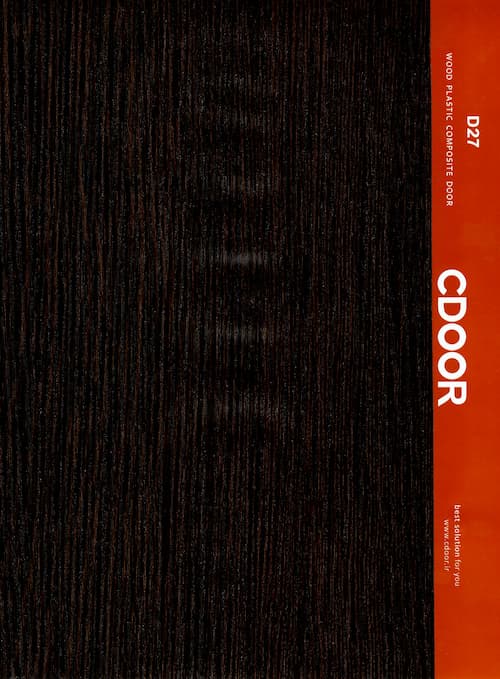

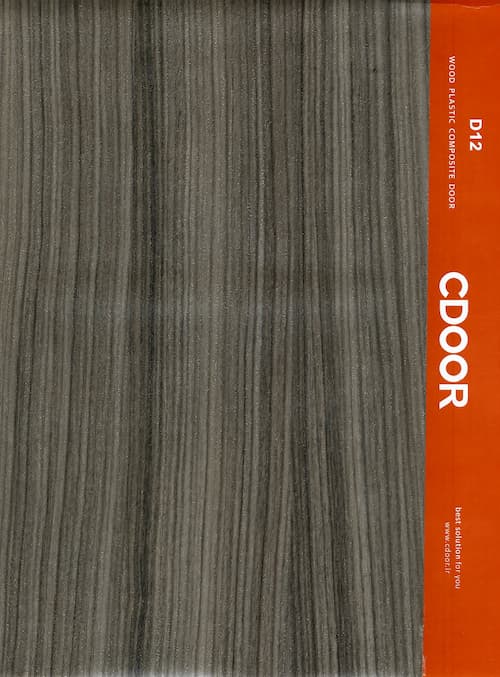

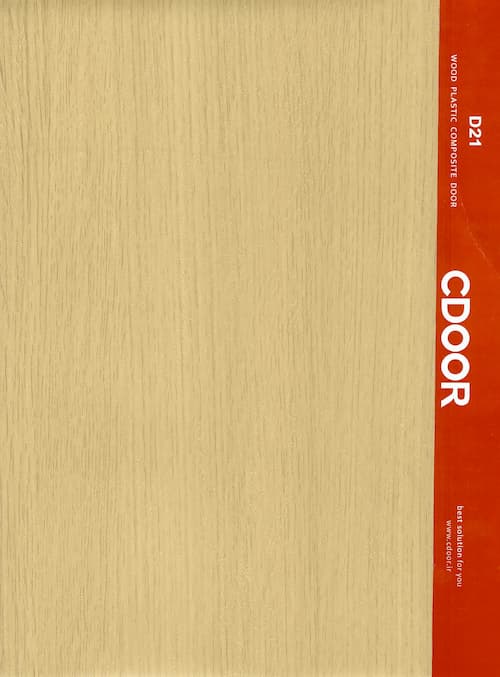

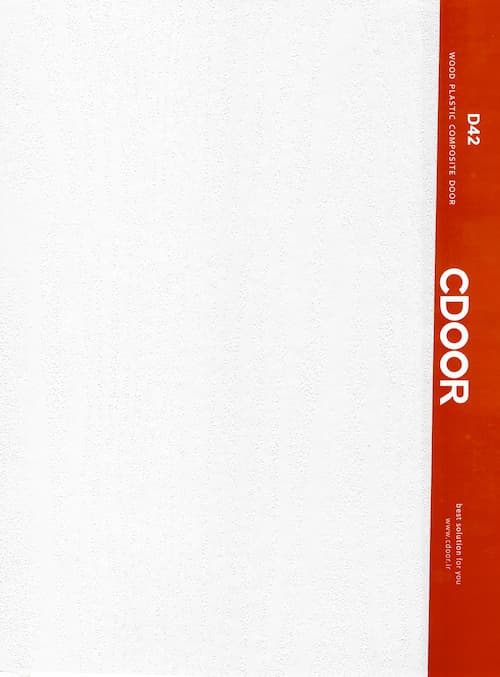

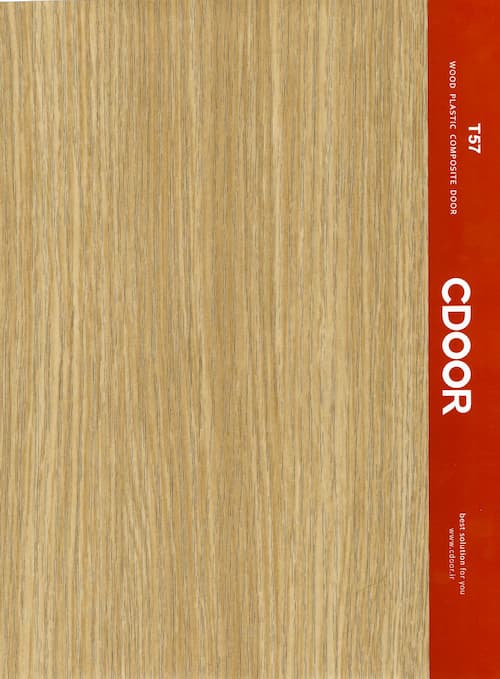

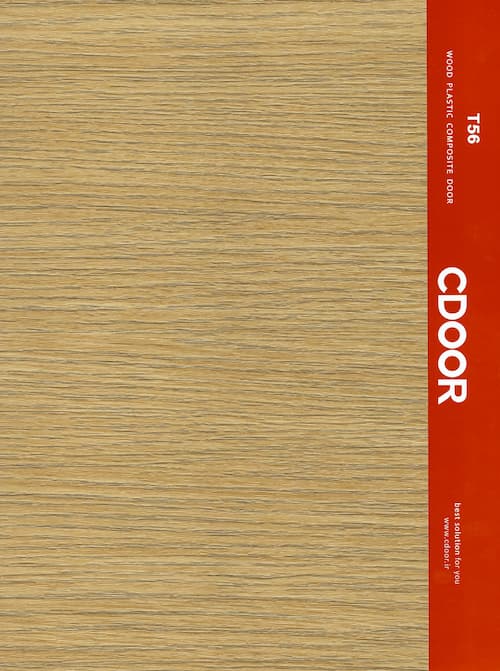

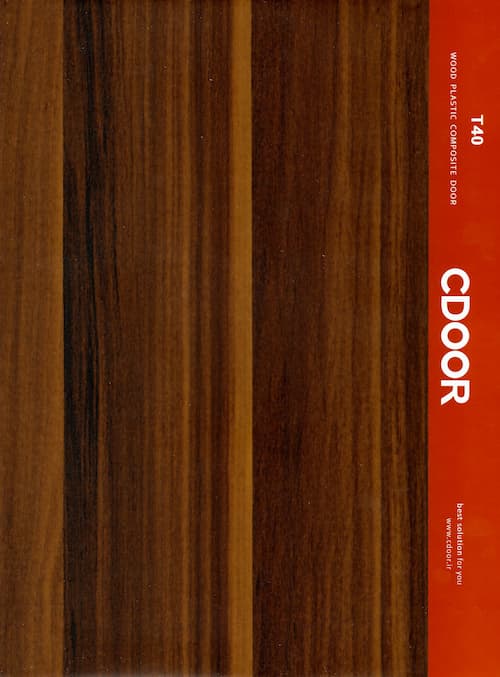

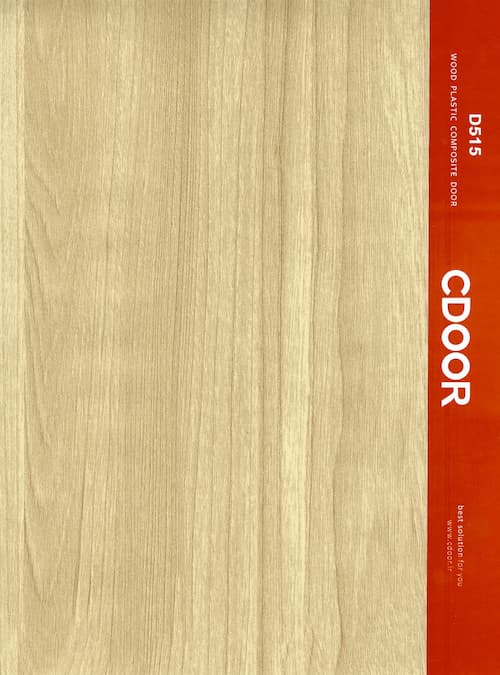

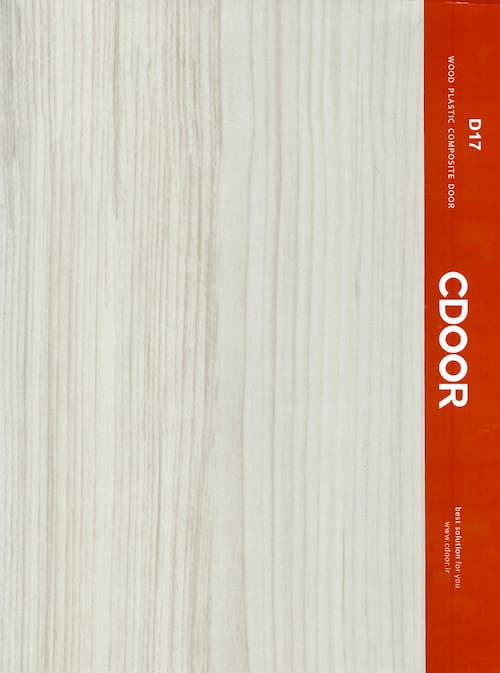

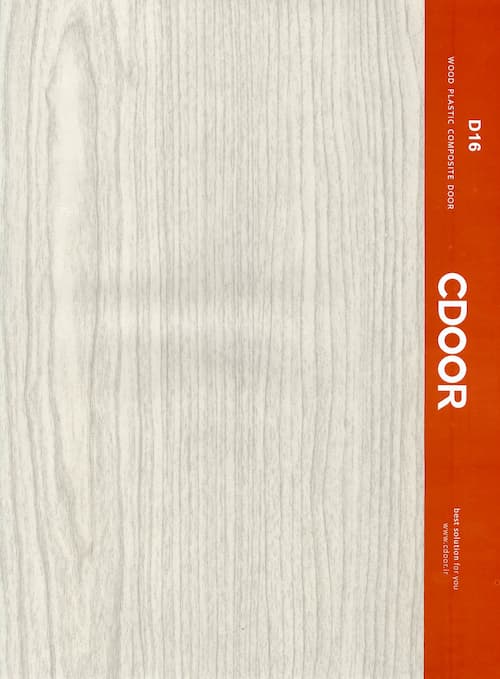

Variety of door and frame cover

In general, you can choose the color of your door from among all the coating codes available.

Fine placement of linear glass horizontally and vertically

In the standard designs available in the company, there are both horizontal and vertical glass designs that can be implemented in different uses depending on the customers' taste.

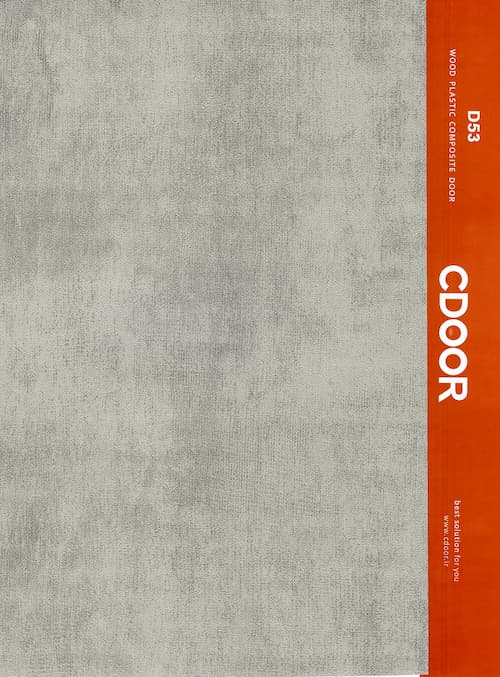

Ability to hide linear glass

If you choose the range of gray colors, the linear glass is somewhat hidden and can only be recognized from a close distance.

Installing a new generation of minimal bed hinges

The minimal bed hinge is more suitable than the normal bed hinge due to the possibility of installation with less wind.

The possibility of installation on different types of frames

It is possible to install it on a wooden and iron frame.

Showing the light on the other side of the ledge

This plan has also taken a look at the vista point (being exposed or visible) of the workplace due to the preservation of privacy (privacy and security) of the user's place. It means that only the light on the other side of the door can be recognized, and other things cannot be seen and recognized.

Variety of door and frame cover

In general, you can choose the color of your door from among all the coating codes available.

Fine placement of linear glass horizontally and vertically

In the standard designs available in the company, there are both horizontal and vertical glass designs that can be implemented in different uses depending on the customers' taste.

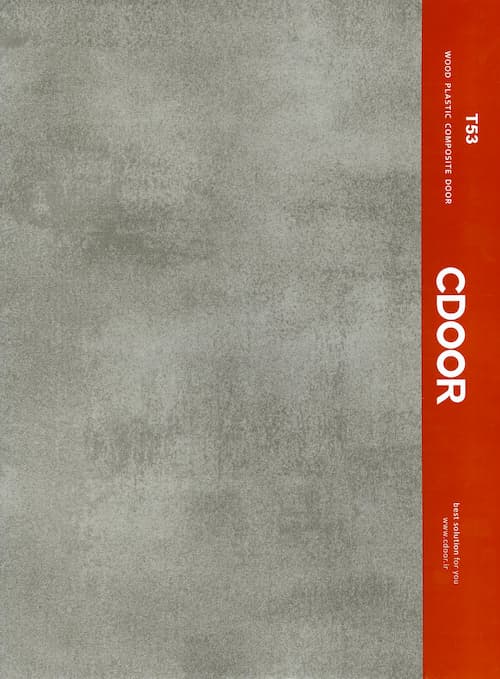

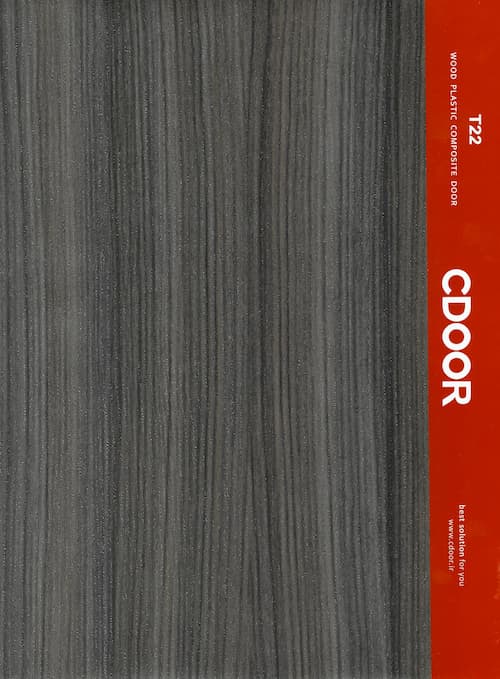

Ability to hide linear glass

If you choose the range of gray colors, the linear glass is somewhat hidden and can only be recognized from a close distance.

Installing a new generation of minimal bed hinges

The minimal bed hinge is more suitable than the normal bed hinge due to the possibility of installation with less wind.

The possibility of installation on different types of frames

It is possible to install it on a wooden and iron frame.

Showing the light on the other side of the ledge

This plan has also taken a look at the vista point (being exposed or visible) of the workplace due to the preservation of privacy (privacy and security) of the user's place. It means that only the light on the other side of the door can be recognized, and other things cannot be seen and recognized.

Variety of door and frame cover

In general, you can choose the color of your door from among all the coating codes available.

Fine placement of linear glass horizontally and vertically

In the standard designs available in the company, there are both horizontal and vertical glass designs that can be implemented in different uses depending on the customers' taste.

Ability to hide linear glass

If you choose the range of gray colors, the linear glass is somewhat hidden and can only be recognized from a close distance.

Installing a new generation of minimal bed hinges

The minimal bed hinge is more suitable than the normal bed hinge due to the possibility of installation with less wind.

The possibility of installation on different types of frames

It is possible to install it on a wooden and iron frame.

Showing the light on the other side of the ledge

This plan has also taken a look at the vista point (being exposed or visible) of the workplace due to the preservation of privacy (privacy and security) of the user's place. It means that only the light on the other side of the door can be recognized, and other things cannot be seen and recognized.

Variety of door and frame cover

In general, you can choose the color of your door from among all the coating codes available.

Fine placement of linear glass horizontally and vertically

In the standard designs available in the company, there are both horizontal and vertical glass designs that can be implemented in different uses depending on the customers' taste.

Ability to hide linear glass

If you choose the range of gray colors, the linear glass is somewhat hidden and can only be recognized from a close distance.

Installing a new generation of minimal bed hinges

The minimal bed hinge is more suitable than the normal bed hinge due to the possibility of installation with less wind.

The possibility of installation on different types of frames

It is possible to install it on a wooden and iron frame.

Be the first to review “Linear Plexiglass door” Cancel reply

Reviews

There are no reviews yet.